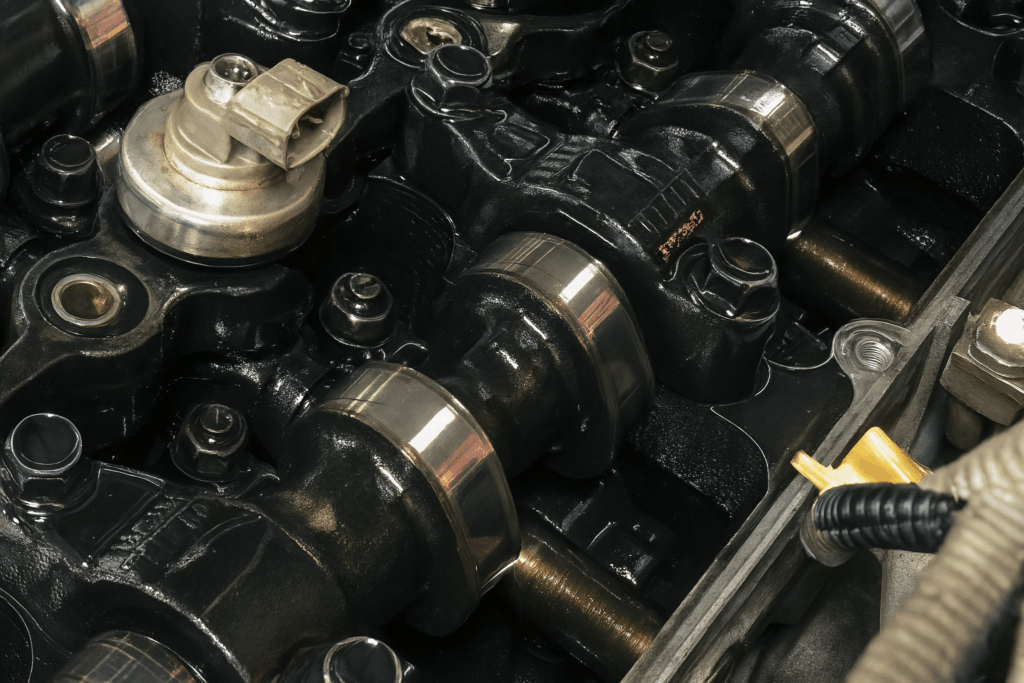

Introduction to Camshaft Bearings

Camshaft bearings are critical components in internal combustion engines, enabling the camshaft to rotate smoothly and maintain precise valve timing. Without high-quality camshaft bearings, engine wear increases, performance declines, and mechanical failures may occur. These bearings play a pivotal role in ensuring efficient operation, reducing friction, and extending the life of both the camshaft and associated engine parts.

Types of Camshaft Bearings

There are several types of camshaft bearings tailored to different engine configurations:

- Babbitt Bearings: Made with a soft metal alloy, ideal for absorbing contaminants and operating under mixed-lubrication conditions.

- Copper-Lead Bearings: Known for their high load-carrying capacity and thermal conductivity.

- Aluminum Alloy Bearings: Lightweight, corrosion-resistant, and suitable for high-speed applications.

- Bi-metal and Tri-metal Bearings: Provide a combination of strength, wear resistance, and conformability.

Each type serves a specific purpose based on engine design and operating demands, from heavy-duty trucks to performance automobiles.

Design Features and Performance Advantages

Camshaft bearings are engineered with precision to ensure:

- Low friction and minimal wear, thanks to finely finished surfaces.

- Exceptional load capacity for supporting rotational forces.

- Enhanced lubrication channels that promote consistent oil distribution.

- Thermal stability for performance in high-temperature environments.

- Corrosion resistance, improving overall bearing life.

By optimizing these features, premium camshaft bearings contribute to fuel efficiency, quieter engine performance, and reduced maintenance needs.

How to Replace Camshaft Bearings

Replacing camshaft bearings involves technical skill and attention to detail. Here’s a general step-by-step overview:

- Disassemble the Engine: Remove components such as the timing chain, cylinder head, and camshaft.

- Extract Old Bearings: Use a specialized cam bearing tool to press out the worn bearings carefully.

- Clean Bearing Journals: Ensure all debris and old lubricant are cleared from the housing.

- Install New Bearings: Align oil holes properly, then press the new bearings into place using a bearing installation tool.

- Reassemble the Engine: Install the camshaft and all previously removed parts, ensuring proper torque and timing settings.

Note: This process varies depending on engine design. Always refer to manufacturer service manuals or consult a professional.

Why Choose Us for Camshaft Bearings?

At Xinbote Bearing Co., Ltd., we supply camshaft bearings from internationally renowned brands such as TIMKEN, SKF, NSK, NACHI, IKO, ASAHI, KOYO, and NTN. With ISO 9001, ISO 14001, and OHSAS 18001 certifications, we guarantee OEM-quality products with global logistics support.

Our advantages include:

- Extensive inventory of camshaft bearings

- Custom bearing solutions for OEM and aftermarket

- Fast international shipping

- Competitive pricing with full technical support

Whether you’re an OEM, repair shop, or distributor, Xinbote offers high-performance camshaft bearings to meet your most demanding applications.

Contact us today or visit our website to learn more and boost your engine performance with world-class precision!