NTN Precision Rolling Bearings are engineered to deliver exceptional performance, durability, and reliability in a wide range of demanding industrial applications. With their advanced design and cutting-edge technology, NTN bearings set the standard for precision engineering. In this article, we will explore the different types and technological innovations behind NTN Precision Rolling Bearings, as well as how Xinbote Bearing Co., Ltd. provides globally recognized bearing solutions that meet the diverse needs of industries worldwide.

Types of NTN Precision Rolling Bearings

NTN offers a comprehensive range of precision rolling bearings, each tailored to meet the specific requirements of different industrial sectors. Some of the key types include:

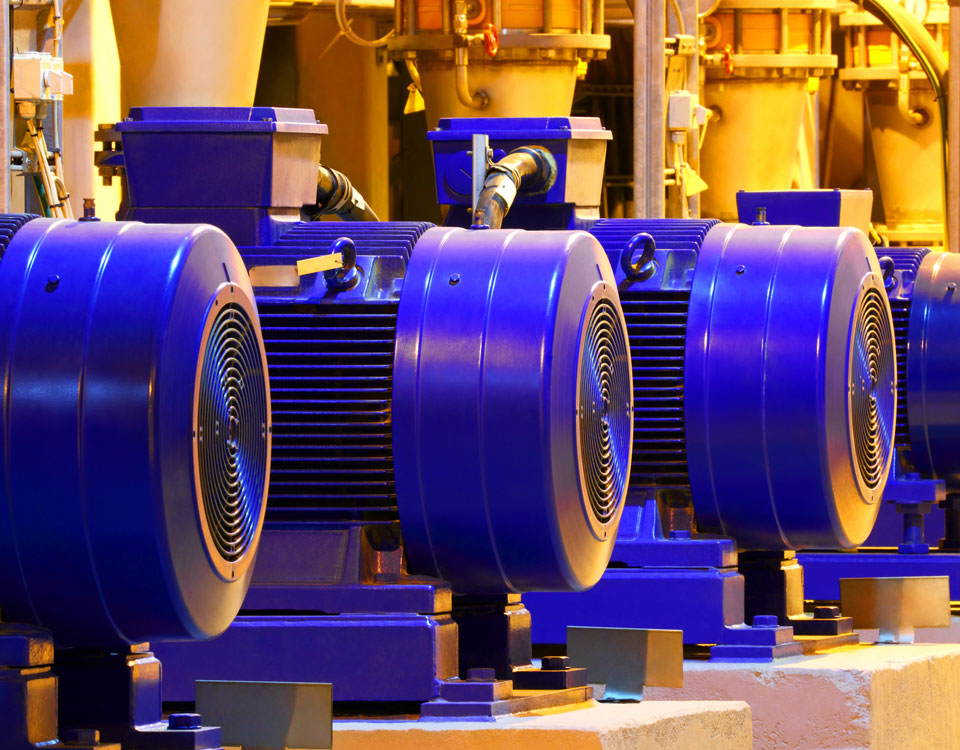

- Deep Groove Ball Bearings: Versatile and robust, NTN’s deep groove ball bearings are ideal for high-speed and high-precision applications. Commonly used in motors, household appliances, and automotive components, these bearings excel in performance even under moderate load conditions.

- Angular Contact Ball Bearings: Designed to handle both radial and axial loads, NTN’s angular contact ball bearings provide superior performance in high-speed applications. These bearings are essential for industries requiring extreme precision, such as aerospace, robotics, and high-performance machinery.

- Cylindrical Roller Bearings: Offering high load capacity and durability, NTN’s cylindrical roller bearings are perfect for heavy-duty applications in industries like mining, steel, and construction. These bearings are designed to endure high radial loads and are often used in applications where space is limited.

- Spherical Roller Bearings: NTN spherical roller bearings are engineered to accommodate misalignment, making them ideal for operations involving high radial loads and rough operating conditions. They are commonly used in industries such as cement, steel, and paper, where misalignment is frequent.

- Tapered Roller Bearings: Known for their ability to handle both radial and axial loads, NTN tapered roller bearings are frequently used in automotive wheel hubs, gearboxes, and heavy-duty machinery applications. These bearings offer superior load handling and long-lasting durability.

Technological Design Features

NTN Precision Rolling Bearings are built with advanced technology and precision manufacturing processes to ensure maximum performance and reliability:

- High-Precision Manufacturing: NTN employs state-of-the-art manufacturing techniques to produce bearings with unmatched precision. This ensures smooth rotation, minimal friction, and long-lasting performance under even the most demanding conditions.

- Advanced Material Selection: NTN uses high-quality materials, such as specialized steels and proprietary coatings, to enhance the bearings’ wear resistance and overall performance. These materials are designed to withstand high-speed rotations, extreme temperatures, and harsh operating environments.

- Sealed Bearings for Extended Life: NTN’s sealed bearings prevent contaminants from entering, offering protection against dirt, moisture, and other harmful substances. This design minimizes friction, extending the bearing’s service life and ensuring smoother operation over time.

- Optimized Lubrication Systems: NTN bearings are equipped with advanced lubrication technologies that reduce friction and improve overall efficiency. This ensures the bearings perform optimally, even in high-load and high-temperature environments.

Advantages of NTN Precision Rolling Bearings

- Superior Durability: NTN Precision Rolling Bearings are designed to last, providing long service life even in the most challenging environments. Their durability helps reduce maintenance costs and ensures operational continuity.

- High-Speed Performance: NTN bearings offer low friction and high rotational speeds, making them ideal for applications that require precision and speed. Whether in automotive engines or industrial robots, NTN bearings ensure smooth, high-speed operation.

- Cost Efficiency: With extended service life and reduced maintenance needs, NTN bearings offer long-term cost savings. Their reliability minimizes downtime and the need for frequent replacements, providing businesses with a cost-effective bearing solution.

- Customizable Solutions: NTN offers a wide array of bearing types and sizes, allowing Xinbote Bearing Co., Ltd. to provide tailor-made bearing solutions for our customers. This customization ensures optimal performance and precise fit for various industrial applications.

Quality Assurance and Global Availability

At Xinbote Bearing Co., Ltd., we pride ourselves on offering NTN Precision Rolling Bearings to a wide range of industries across the globe. Our manufacturing facility uses cutting-edge technology, ensuring that each bearing meets rigorous international quality standards. From automotive to aerospace and heavy machinery, our NTN bearings are used in numerous industries, ensuring peak performance in even the most demanding environments.

As a leading global bearing supplier, we provide fast, reliable delivery to clients worldwide. Our bearing solutions are trusted by customers in countries such as Poland, Canada, India, Italy, Germany, and more.

Conclusion

NTN Precision Rolling Bearings represent the pinnacle of engineering, offering exceptional performance, durability, and reliability. Whether for high-speed operations or heavy-duty machinery, NTN bearings provide the precision and endurance required by industries worldwide. By partnering with Xinbote Bearing Co., Ltd., you can access top-quality NTN bearings that meet your unique industrial needs.

Contact us today to learn more about NTN Precision Rolling Bearings or to request customized bearing solutions tailored to your application.