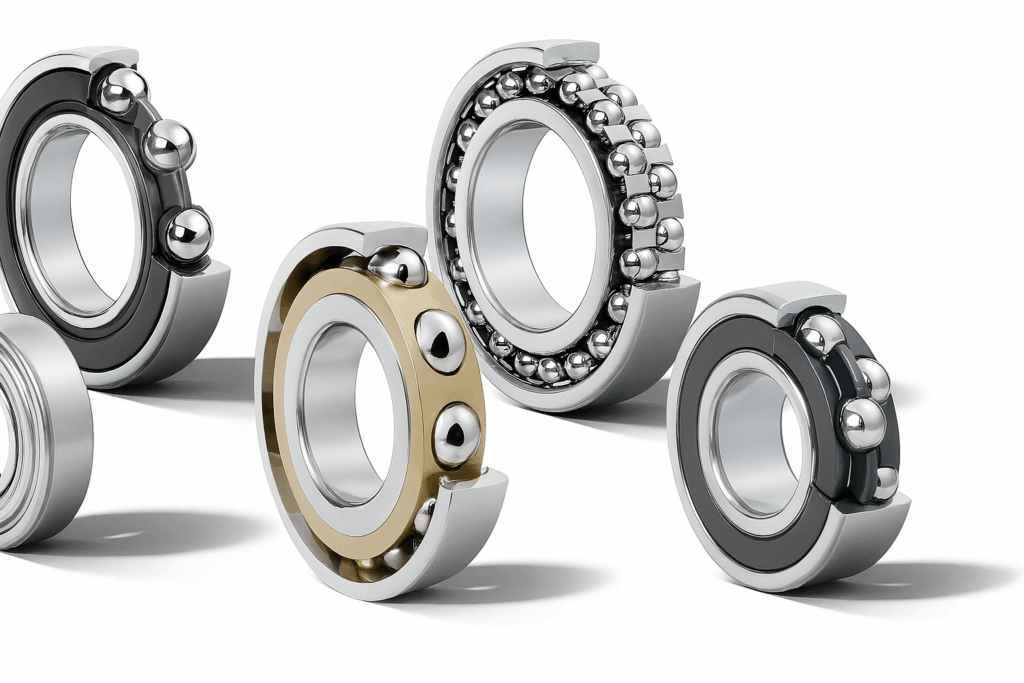

Ball bearings are the cornerstone of modern mechanical systems, enabling smooth rotation, reducing friction, and extending equipment lifespan. From automotive to industrial applications, understanding how ball bearings work—and the differences between their types—is essential for engineers, procurement teams, and machine operators worldwide.

What Are Ball Bearings and How Do They Work?

Ball bearings are mechanical components that reduce rotational friction and support radial and axial loads. They consist of a series of hardened steel or ceramic balls positioned between two smooth metal races. As the inner race rotates, the balls roll instead of slide, which significantly minimizes friction and allows for efficient motion transmission even under high-speed or heavy-load conditions.

Main Types of Ball Bearings

Choosing the right type of ball bearing depends on load direction, speed, and application environment. Here are the most common types:

Deep Groove Ball Bearings

· Most widely used type

· Suitable for high-speed and moderate-load applications

· Handles both radial and limited axial loads

· Common in electric motors, gearboxes, and home appliances

Angular Contact Ball Bearings

· Designed to carry combined radial and axial loads

· Ideal for high-precision applications like machine tool spindles

· Available in single-row and double-row designs for increased load capacity

Self-Aligning Ball Bearings

· Automatically correct misalignments between the shaft and housing

· Ideal for applications where shaft deflection or mounting errors are expected

· Commonly used in conveyor systems and agricultural machinery

Thrust Ball Bearings

· Built to handle axial loads only

· Typically used in low-speed applications like turntables and low-load gearboxes

Key Design Features of Ball Bearings

· High-Grade Materials: Made from stainless steel, carbon steel, or ceramic to ensure durability and load resistance

· Precision Tolerances: Engineered for minimal vibration and noise, especially important in high-speed applications

· Advanced Sealing and Shielding: Prevent contamination and retain lubricant for longer service life

· Lubrication Systems: Either pre-lubricated or designed to work with oil/grease systems for smooth operation

Applications Across Industries

· Automotive: Transmission, wheels, engine systems

· Aerospace: Jet engines, flight controls

· Manufacturing: Robotics, CNC machines, conveyor belts

· Home Appliances: Fans, washing machines, vacuum motors

· Medical Equipment: MRI systems, dental tools

Global Supplier of Premium Bearings

Xinbote Bearing Co., Ltd. is a leading manufacturer and international distributor of high-quality bearings based in China. With over 20,000 square meters of advanced manufacturing space, we specialize in the R&D, production, and global export of premium bearing solutions.

We are proud to be authorized distributors of world-renowned brands including: SKF, NSK, TIMKEN, KOYO, NTN, IKO, ASAHI, and NACHI.

Backed by certifications such as ISO 9001, ISO 14001, and OHSAS 18001, our bearings are trusted in industries ranging from power generation and mining to automotive and aerospace.

Why Choose Xinbote?

· Wide product range including deep groove, angular contact, and thrust ball bearings

· Custom bearing solutions tailored to specific industrial needs

· Fast international shipping and reliable global support

· Strict quality control for consistent performance and durability

Looking for a trusted global ball bearing supplier? Contact Xinbote Bearing Co., Ltd. today to explore our full product catalog and discover how we can support your machinery with world-class bearing technology.